SMALL PERMANENT MAGNETIC SEPARATORS

-

SEPARATORS FERRITE

-

SEPARATORS RARE-EARTH

FERRITE MAGNETIC TUBES

FERRITE MAGNETIC TUBES

Ferrite Magnetic Tubes can be used to remove iron contamination from liquids in tanks or as a random quality control check of dry bulk material. The magnetic tubes are available with solid, studded or threaded tubes ends. These magnetic tubes form the basic building block for Rare Earth Grid Magnets and Ferrous Traps.

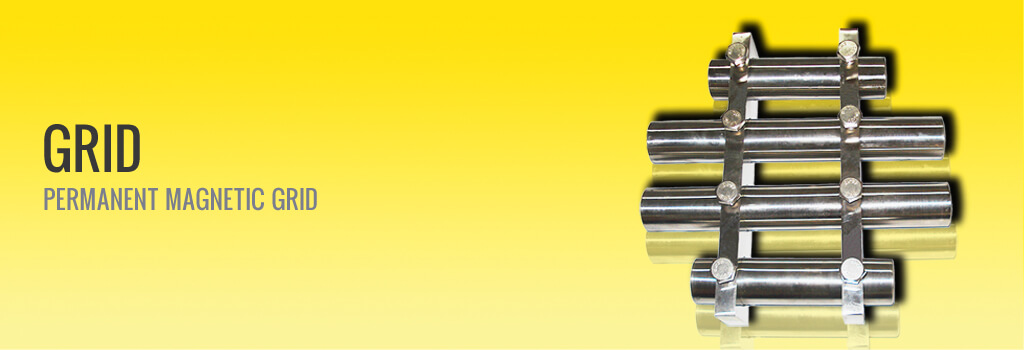

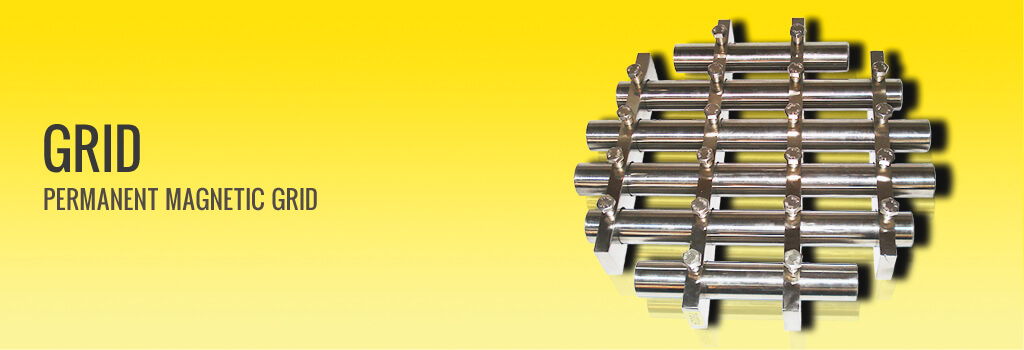

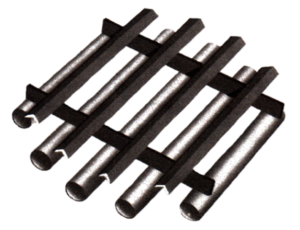

GRIDS

FERRITE MAGNETIC GRIDS are used for permanent protection against fine or weakly magnetic iron. They are designed’-.for simple installation in hoppers, floor openings, vertical closed chutes, ducts, etc.

Grids are available in single, double or multiple bank configuration depending on customer requirement. They can be supplied either in square, rectangular or circular construction to suit customer installation. They can also be supplied in specially designed housing with separately mounted vibrator for ensuring free movement of sticky material if required.

GRIDS

FERRITE MAGNETIC GRIDS are used for permanent protection against fine or weakly magnetic iron. They are designed’-.for simple installation in hoppers, floor openings, vertical closed chutes, ducts, etc.

Grids are available in single, double or multiple bank configuration depending on customer requirement. They can be supplied either in square, rectangular or circular construction to suit customer installation. They can also be supplied in specially designed housing with separately mounted vibrator for ensuring free movement of sticky material if required.

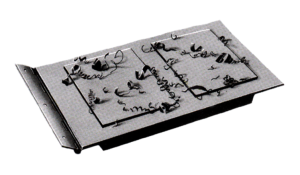

PERMANENT PLATE MAGNETS

ELEKTROMAG Permanent Plate Magnet can be installed in any position, in any condition – in hot, cold or wet locations, on vibrating equipment to trap tramp iron from a wide range of dry, wet, solid, materials.

ELEKTROMAG Plate Magnet is a powerful, dependable, permanent protection of costly machinery and products against tramp iron contamination. It is designed for easy installation in ducts, feedtables and housings, and also for suspension over screens, moving conveyors, etc.

PERMANENT PLATE MAGNETS

ELEKTROMAG Permanent Plate Magnet can be installed in any position, in any condition – in hot, cold or wet locations, on vibrating equipment to trap tramp iron from a wide range of dry, wet, solid, materials.

ELEKTROMAG Plate Magnet is a powerful, dependable, permanent protection of costly machinery and products against tramp iron contamination. It is designed for easy installation in ducts, feedtables and housings, and also for suspension over screens, moving conveyors, etc.

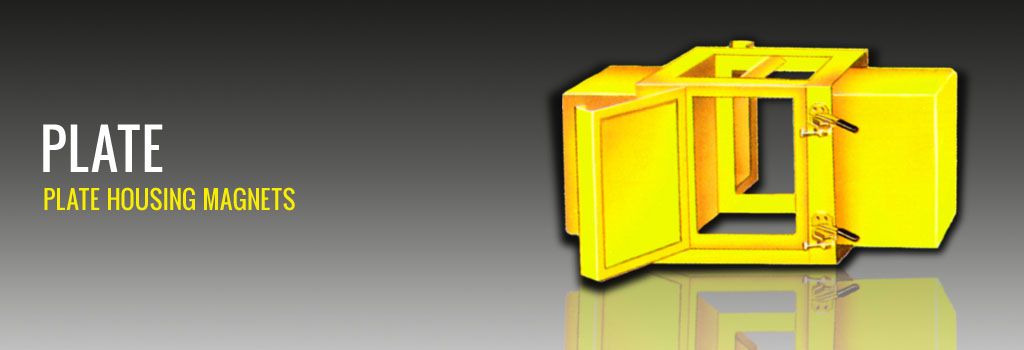

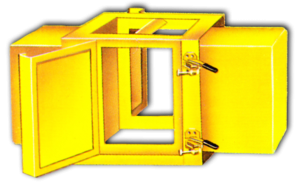

PLATE HOUSING MAGNETS

This is a newly introduced product with an outstanding feature. The Plate Housing Magnet is effective in vertical chutes where powder and coarse material fall freely passing through the housing.

The Plate Housing Magnet is designed for Magnetic Separation of nearly any size of material. The tramp iron is securely held by the two magnetic walls in the throat while the flow continues.

This Separator is best where space is a constraint because of which other Separators cannot be used.

PLATE HOUSING MAGNETS

This is a newly introduced product with an outstanding feature. The Plate Housing Magnet is effective in vertical chutes where powder and coarse material fall freely passing through the housing.

The Plate Housing Magnet is designed for Magnetic Separation of nearly any size of material. The tramp iron is securely held by the two magnetic walls in the throat while the flow continues.

This Separator is best where space is a constraint because of which other Separators cannot be used.

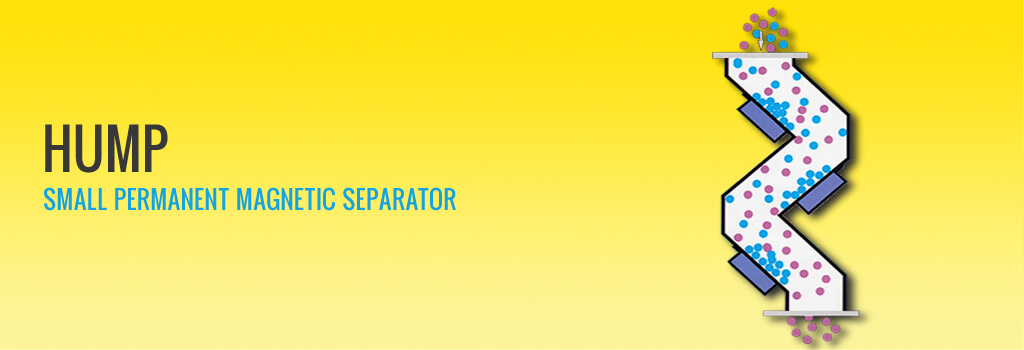

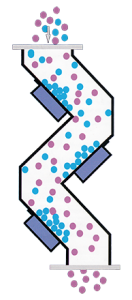

HUMPS

ELEKTROMAG Permanent Magnetic Humps are used where the flow of material is vertical through ducts and pipes and where material is conveyed along horizontal pneumatic lines.

The unit incorporates two permanent magnetic plates positioned so that tramp iron contained in the flow of materials is directed towards the poles of both the magnetic plates ensuring maximum magnetic extraction. The tramp iron pieces usually have a greater density than the feed material and hence increases the tendency for them to move towards the magnet.

The two Permanent Magnetic Plates are hinged type and can be easily opened for manual cleaning.

HUMPS

ELEKTROMAG Permanent Magnetic Humps are used where the flow of material is vertical through ducts and pipes and where material is conveyed along horizontal pneumatic lines.

The unit incorporates two permanent magnetic plates positioned so that tramp iron contained in the flow of materials is directed towards the poles of both the magnetic plates ensuring maximum magnetic extraction. The tramp iron pieces usually have a greater density than the feed material and hence increases the tendency for them to move towards the magnet.

The two Permanent Magnetic Plates are hinged type and can be easily opened for manual cleaning.

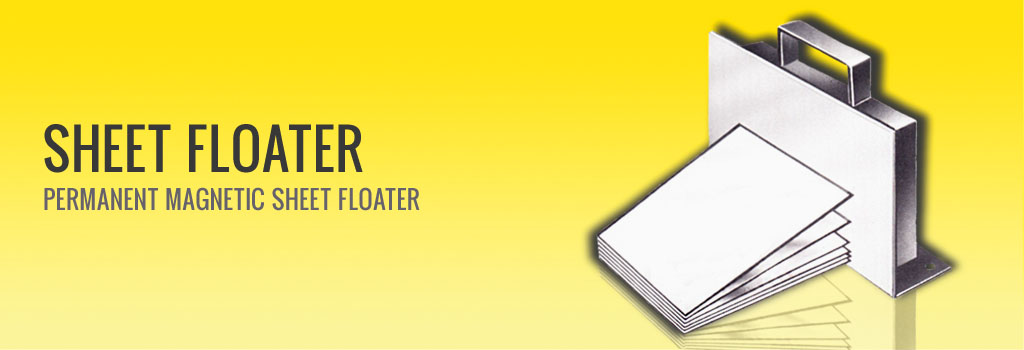

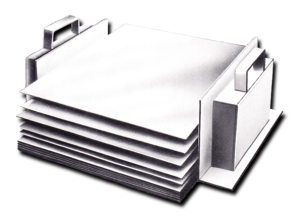

MAGNETIC SHEET FLOATERS

Elektromag Magnetic Sheet Floaters have been designed for easy handling of stacked sheets in production jobs. It cuts costs on job where steel sheets are handled in production by eliminating the need to fumble with thin oily sheets.

HOW IT WORKS:

A Sheet Floater is positioned against the stack of steel sheets. The magnetic field passes in the steel sheets and they become magnetised in the area touching the sheet floater. As a result, the sheets near the top of the stack separate as there is no load on the top sheet. When the topmost sheet is removed the next lower sheet automatically moves up. This action repeats until all sheets have been removed.

MAGNETIC SHEET FLOATERS

Elektromag Magnetic Sheet Floaters have been designed for easy handling of stacked sheets in production jobs. It cuts costs on job where steel sheets are handled in production by eliminating the need to fumble with thin oily sheets.

HOW IT WORKS:

A Sheet Floater is positioned against the stack of steel sheets. The magnetic field passes in the steel sheets and they become magnetised in the area touching the sheet floater. As a result, the sheets near the top of the stack separate as there is no load on the top sheet. When the topmost sheet is removed the next lower sheet automatically moves up. This action repeats until all sheets have been removed.

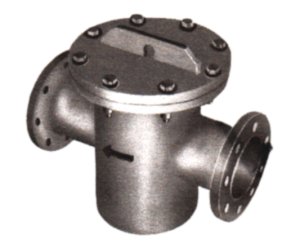

FERROUS TRAPS

PERMANENT MAGNETIC FERROUS TRAPS are suitable for installation in pipeline. The magnetic tubes within the trap device catch the tramp and fine iron contamination in the product as it flows through the processing line thereby protecting product purity and preventing abrasive wear. The use of this ferrous trap in the pipeline also offers other benefits such as preventing pumps from jamming, reduce damage and maintenance to mixers, refiners, filters, pumps and other processing equipment.

The special design enables quick release of the magnet tubes for easy inspection and cleaning.

FERROUS TRAPS

PERMANENT MAGNETIC FERROUS TRAPS are suitable for installation in pipeline. The magnetic tubes within the trap device catch the tramp and fine iron contamination in the product as it flows through the processing line thereby protecting product purity and preventing abrasive wear. The use of this ferrous trap in the pipeline also offers other benefits such as preventing pumps from jamming, reduce damage and maintenance to mixers, refiners, filters, pumps and other processing equipment.

The special design enables quick release of the magnet tubes for easy inspection and cleaning.

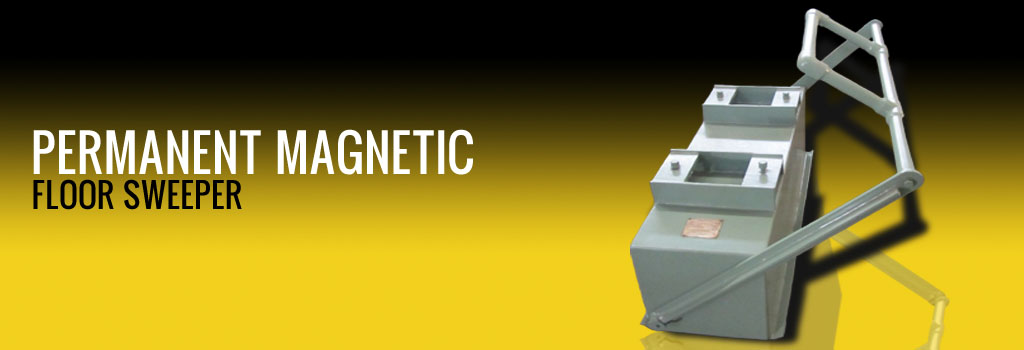

FLOOR / ROAD SWEEPERS

FLOOR / ROAD SWEEPERS

MAKE A CLEAN PROFITABLE SWEEP

“ELEKTROMAG” MAGNETIC FLOOR SWEEPER is the most effective and economical answer to damaging nails, screws, rods and dangerous scrap metal of all kinds lying scattered on roadways and factory premises. The Magnetic Sweeper can pick up everything from fine iron to heavy bolts, nuts, washers, screws, turning, borings, rivets, nails, pins, staples etc., lying on the floor.

APPLICATION

The Magnetic Sweeper finds wide application in machine shops, repairshops, garages, metal working assembly plants, scrap yards, ships, warehouses, building constructions, airports and parking lots. A considerable amount of time is saved in magnetically sweeping up and reclaiming ferrous trash by this process instead of manually brushing the floor. The considerable savings resulting from the use of this Sweeper makes it pay for itself within a short time. Furthermore, the Magnetic Sweeper helps prevent accidents by removing sharp edged objects that could penetrate shoes or injure bare feet. Also, steel chips, turning embedded in shoes cause damage to office furnishings such as carpeting, flooring etc.

RANGE

HAND OPERATED MODELS

Floor Clearance 40mm

Standard sweeping widths: 300,450, 600, 750, 900 mm

EASY TO USE

The Hand Operated Magnetic Sweeper is of all steel construction. The main important feature of this sweeper is the use of powerful everlasting permanent magnets. An extra steel bottom plate is hinged to the main body. This plate intercepts the attracted metal and holds it securely. When the attached metal is to be released off the Sweeper away, just pull the lever and move the sweeper. All the metal immediately drops off. The Sweeper is ready for more sweeping as soon as the lever is moved backwards. Two wheels are provided for easy maneuvering.

OTHER BIGGER MODELS

For large scale applications Trailer Models, Bracket Models, Fork Lift Models are available for attachment to Trucks, Tractors, Jeeps, Fork lift Trucks & other vehicles.

Floor Clearance : 40 mm to 125 mm. Standard Sweeping width range: ‘l2OO mm to 2400 mm. Magnetic Sweeping is automatic when Sweeper is carried/towed over road surfaces at prescribed floor clearance/speed. Accumulated iron pieces are easily released by simply moving Hand Lever from ‘pick up’ to ‘discharge’ position.

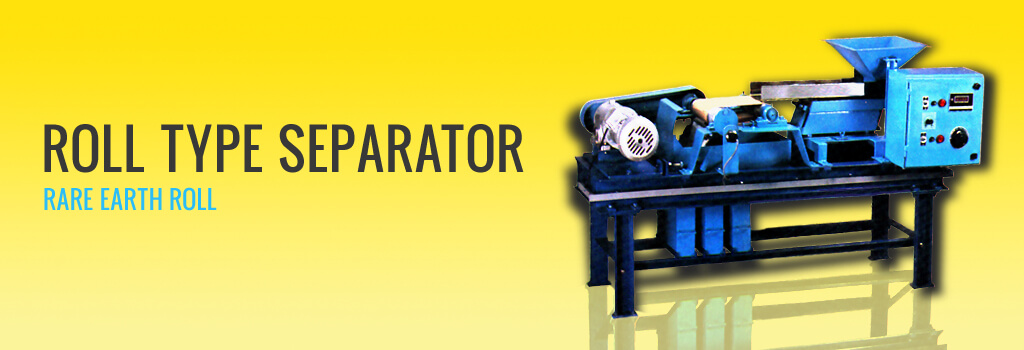

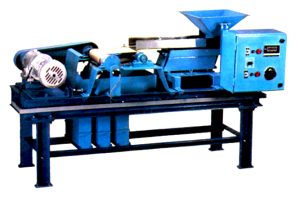

RARE EARTH ROLLS

RARE EARTH ROLLS

RARE EARTH ROLLS are used as head pulleys to purify or concentrate dry materials conveyed on thin,abrasion resistant belts,They are widely used for separations of weakly magnetic or fine iron contamination from range of a minerals such as Abrasives, Glass Sands, Bauxite upgrading, Beach Sands, Ceramic Raw materials, Chromite Ores, Diamond Ores, Graphite, Iron Ore, Manganese Ores, PET Plastics, Quartz, Refractory, Silica Minerals and several other applications.They are available as independent units or assembled into conveyor/separator machines as required.

The Rolls are available as standard 76 mm dia. Or 102 mm dia . and in widths upto 1000 mm.

ROD

Rare Earth Magnetic Tubes can be used to remove iron contamination from liquids in tanks or as a random quality control check of dry bulk material. The magnetic tubes are available with solid, studded or threaded tubes ends. These magnetic tubes form the basic building block for Rare Earth Grid Magnets and ferrous Traps.

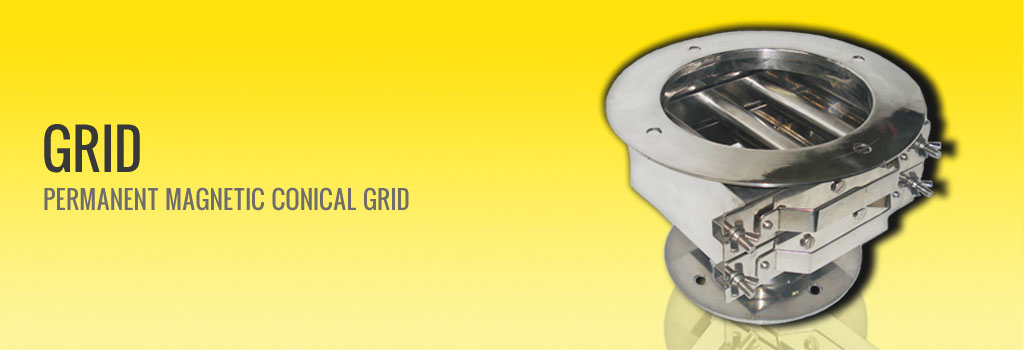

GRIDS

RARE EARTH MAGNETIC GRIDS are used for permanent protection against fine or weakly magnetic iron. They are designed’-.for simple installation in hoppers, floor openings, vertical closed chutes, ducts, etc.

Grids are available in single, double or multiple bank configuration depending on customer requirement. They can be supplied either in square, rectangular or circular construction to suit customer installation. They can also be supplied in specially designed housing with separately mounted vibrator for ensuring free movement of sticky material if required.

PLATE

RARE EARTH PLATE Magnets are widely used to remove weakly magnetic and fine iron contamination. They are designed for easy installation in feed chutes and also for suspension over product flow.

Rare Earth Plate Magnets can be used to purify food. Chemical and pharmaceutical products like powders, grains and resins, minerals such as talc, silica and slurried products like ceramic slips and glazes. For more information please call for our Plate Magnet catalog.

Rare Earth Hump Magnets can also be supplied for installation in ducts.

HUMPS

ELEKTROMAG Permanent Magnetic Humps are used where the flow of material is vertical through ducts and pipes and where material is conveyed along horizontal pneumatic lines.

The unit incorporates two permanent magnetic plates positioned so that tramp iron contained in the flow of materials is directed towards the poles of both the magnetic plates ensuring maximum magnetic extraction. The tramp iron pieces usually have a greater density than the feed material and hence increases the tendency for them to move towards the magnet.

The two Permanent Magnetic Plates are hinged type and can be easily opened for manual cleaning.

FERROUS TRAPS

RARE EARTH PIPELINE FERROUS TRAPS can be installed in pipelines handling pulp, slurries, and inks, liquid food etc. They have a magnetic element, consisting of a group of magnetic tubes which causes the material flow entering the body to impinge against the tubes-and filter through the magnetic field, which completely covers the open area. This magnetic combing action combined with the Rare Earth Magnetic power provides optimum removal of fine ferrous contamination. The pressure drop through the unit is no more than that of a 900 elbow. Rare Earth Ferrous Traps are available in a wide range for pipelines ranging from 50 mm dia to 600 mm dia.